Concrete Lifting & Leveling in Kansas City, MO

Fast, Clean, Built to Last

50+ years of experience. 20,000+ concrete lifting projects nationwide.

Fast, clean concrete lifting in Kansas City, MO.

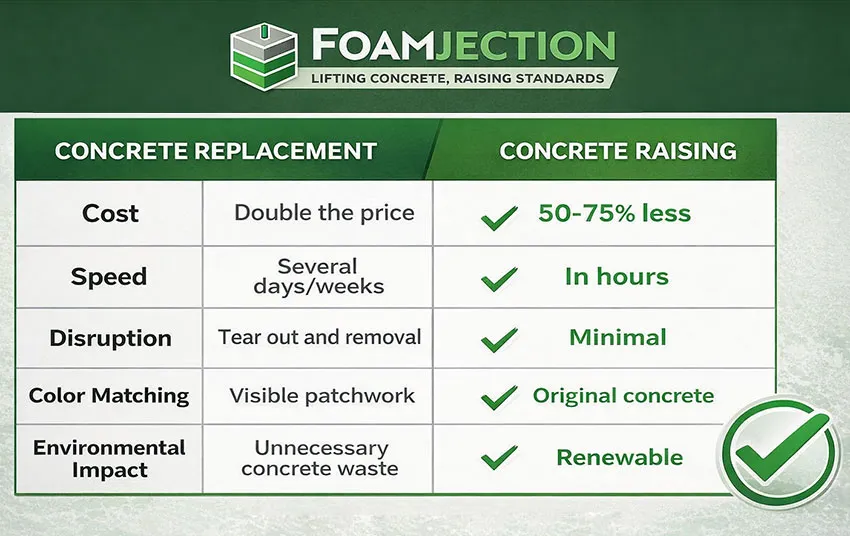

Most projects take hours, not days, and cost 50–70% less than replacement.

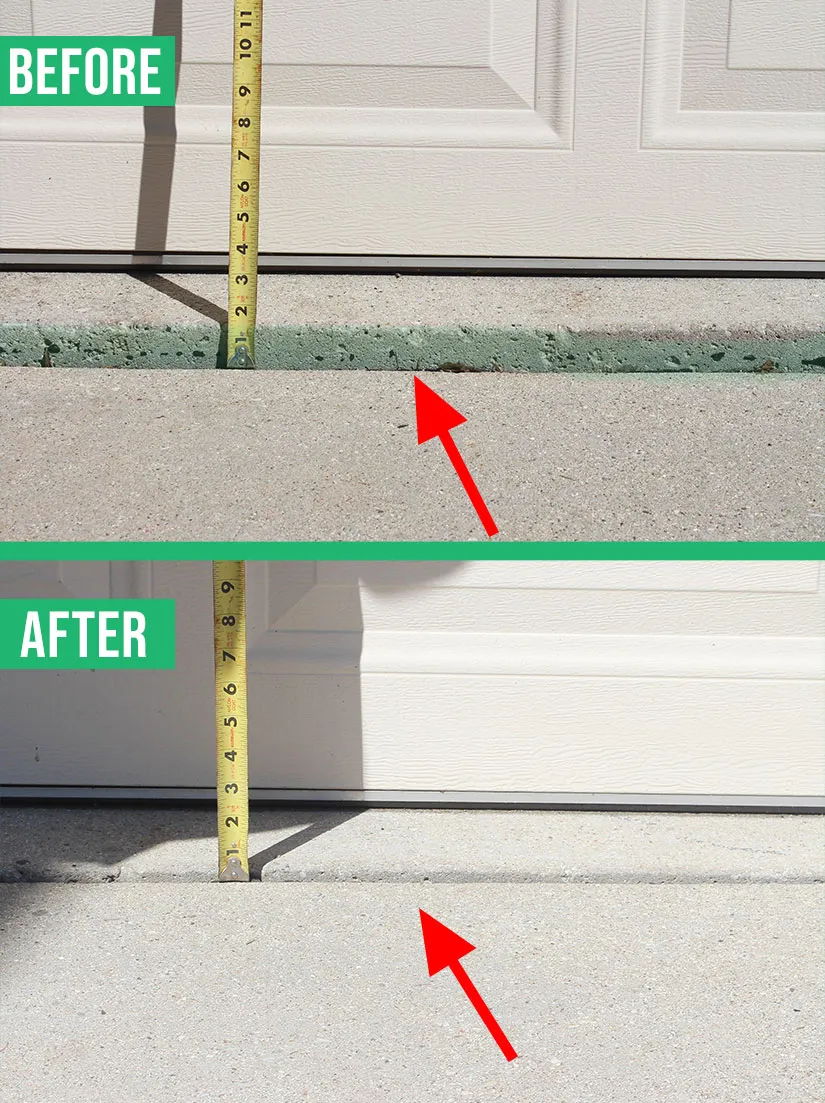

The Problem: Uneven Concrete

Uneven slabs create trip hazards, drainage problems, and surface damage that worsen over time.

The Solution: Concrete Lifting

Concrete lifting restores a level surface by raising the slab from below. It’s fast, clean, cost-effective, and avoids concrete replacement.

FREE NO-PRESSURE ESTIMATES

The Smarter Way to Fix Sinking Concrete in Kansas City, MO

If your driveway, sidewalk, patio, porch, steps, garage floor, concrete floor, or pool deck in Kansas City, MO is sinking or uneven, replacement is not your only option. Foamjection provides professional concrete lifting and leveling in Kansas City using high-density polyurethane foam.

Our polyurethane concrete leveling process—also known as polyjacking or slabjacking—lifts settled concrete from below, fills voids, and restores support without demolition. Most residential projects in Kansas City are completed in hours, not days, and surfaces are often ready for use the same day.

The Smarter Way to Fix Sinking Concrete in Kansas City, MO

Save Up to 70% vs. Replacement

Our foam concrete leveling process avoids demolition, hauling, and new concrete costs — delivering a long-lasting fix at a fraction of the price.

Fast, Clean & Non-Invasive

Precise injection points and lightweight equipment allow most projects to be completed in hours, not days, with minimal disruptions.

Built for Long-Term Stability

Built for Long-Term Stability

High-density eco-friendly, polyurethane foam fills voids, strengthens weak soil, and resists water and erosion to help prevent future settlement.

Backed by 50+ years of industry experience, Foamjection delivers consistent results using proven materials, methods, and standards on every project. Our system is designed to lift, level, and stabilize concrete at its source — addressing the soil and voids beneath the slab, not just the surface problem.

Residential Concrete Lifting That Saves

You Time & Money

Fast, clean polyurethane lifting for settled concrete around your home.

Driveway Leveling

Lift and stabilize sunken driveways without tearing out concrete.

Garage Floor Leveling

Raise settled garage slabs to restore safety and proper drainage.

Walkway & Sidewalk Leveling

Eliminate trip hazards by lifting uneven walkways and sidewalks.

Steps Leveling

Level sinking concrete steps for safer, more secure entryways.

Porch Leveling

Stabilize sinking porches and protect your home’s entry point.

Patio Leveling

Re-level patios to stop pooling water and uneven surfaces.

Concrete Slab Leveling

Lift settled concrete slabs by filling voids beneath the surface.

Concrete Floor Leveling

Restore interior and exterior concrete floors without disruption.

Pool Deck Leveling

Lift uneven pool decks to improve safety and appearance.

FREE NO-PRESSURE ESTIMATES

Commercial Concrete Leveling Built for

Safety & Longevity

Reliable foam lifting solutions built for safety, scale, and durability.

Warehouse Floors

Stabilize floors without interrupting production.

Municipal

Reliable leveling & stabilization for public infrastructure.

Seawall Repair

Stabilize concrete seawalls and prevent further soil loss.

Void Filling

Restore support beneath concrete by filling hidden voids.

Highways

Correct settled slabs to improve ride quality and safety.

Strip Malls

Repair uneven concrete while keeping businesses open.

Interior Floor Leveling

Lift interior concrete floors with minimal disruption to operations.

Factory Floors

Level high-traffic warehouse floors to support heavy loads safely.

Churches

Level concrete surfaces while preserving the structure and appearance.

Airport Runways & Hangars

Stabilize critical concrete surfaces with precision foam lifting.

Loading Docks & Ramps

Correct uneven docks and ramps to improve safety and access.

Schools

Improve safety across campus walkways and concrete surfaces.

Hotels

Restore guest areas quickly without long closures or tear-outs.

Hospitals

Address uneven concrete with clean, low-disruption solutions.

Parking Lots

Raise settled parking lot slabs to reduce hazards and liability.

Senior Centers

Reduce trip hazards with smooth, stable concrete surfaces.

How Foam Injection Works

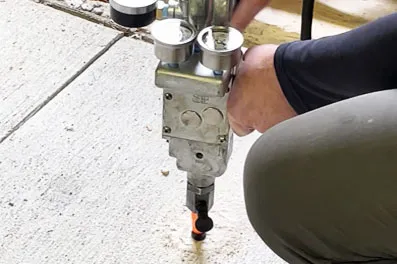

Drill Small Holes

Drill Small Holes

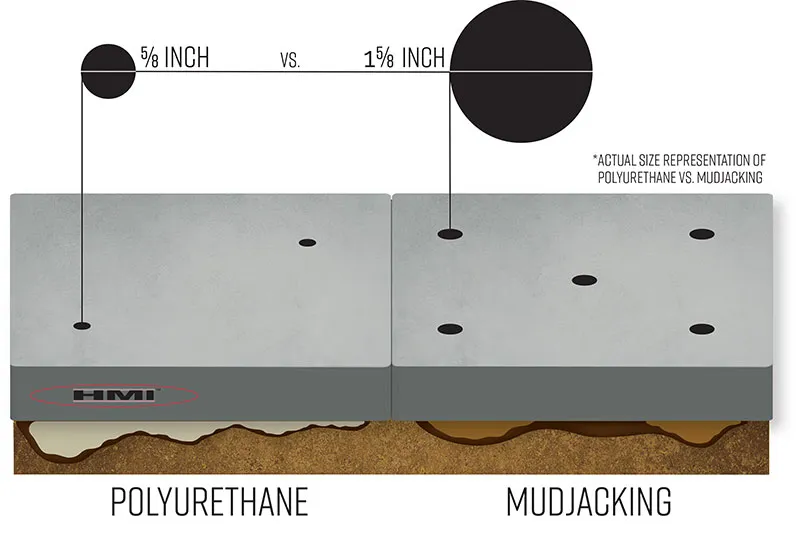

Our crew drills small 5/8″ holes in key areas of the slab.

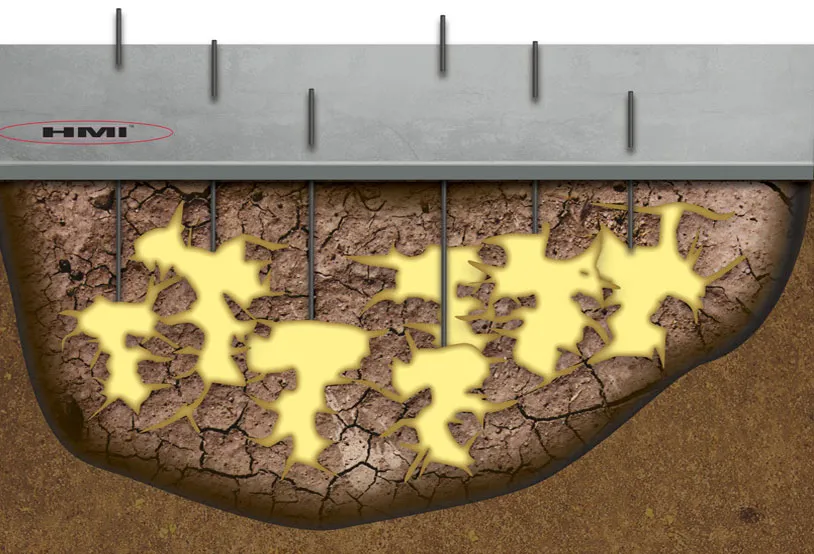

Inject High-Density Polyurethane Foam

Inject High-Density Polyurethane Foam

This is the core of polyurethane concrete lifting — the foam expands beneath the slab, fills voids, stabilizes loose soils, and delivers a controlled slab lifting process.

Patch & Use the Same Day

Patch & Use the Same Day

Once the slab reaches the correct height, holes are patched and the area is often ready to use within hours.

Testimonials From Real Homeowners

My driveway looks brand new after the slab lifting — and it was done in one afternoon.

Polyurethane concrete lifting saved us thousands compared to replacement.

Fast, clean, and no damage to our landscaping. Foam lifting works exactly as they explained.

Frequently Asked Questions

How It Works

How do you fix sinking concrete?

Foamjection fixes sinking concrete by injecting high-density polyurethane foam beneath the slab. Small holes are drilled, and the foam is injected into weak or empty areas under the concrete. As the foam expands, it fills voids, stabilizes the soil, and gently lifts the slab back into position—all without removing or replacing the concrete. Learn more about the full process.

What causes concrete to sink in Kansas City?

Concrete usually sinks because the soil beneath it weakens or shifts over time. This can happen due to poor soil compaction during construction, water erosion, drainage issues, freeze-thaw cycles, or washout around the slab. When the soil loses strength, the concrete no longer has solid support and begins to settle unevenly.

What kind of material do you use to raise concrete?

Foamjection uses high-density polyurethane foam to raise, level, and stabilize concrete. The material starts as a liquid and is injected beneath the slab, where it expands to fill hidden voids, strengthen weak soil, and gently lift the concrete back into position.

Once cured, the foam becomes a durable, moisture-resistant solid that does not break down in wet conditions or add unnecessary weight to already unstable soil. Because the foam is lightweight yet strong, it helps support the slab without contributing to future settlement.

Compared to traditional mudjacking materials, polyurethane foam requires fewer and smaller injection holes, making the repair far less noticeable. The process is also cleaner, faster, and more precise, with most surfaces ready for use the same day.

Foamjection’s polyurethane foam is designed for long-term performance and environmental responsibility. It contains renewable content, does not leach harmful chemicals into the soil or groundwater, and eliminates the need for concrete tear-out and landfill waste. By lifting and stabilizing existing concrete instead of replacing it, homeowners get a lasting repair that’s better for their property — and the environment.

What is the difference between mudjacking and polyurethane concrete raising?

Mudjacking uses a heavy cement-based slurry to lift concrete, while polyurethane lifting uses lightweight expanding foam. Foam requires smaller holes, adds very little weight to the soil, cures faster, and offers more precise control during lifting. Because of this, polyurethane lifting is often cleaner, faster, and longer-lasting than traditional mudjacking.

Mudjacking uses a heavy cement-based slurry to lift concrete, while polyurethane lifting uses lightweight expanding foam. Foam requires smaller holes, adds very little weight to the soil, cures faster, and offers more precise control during lifting. Because of this, polyurethane lifting is often cleaner, faster, and longer-lasting than traditional mudjacking.

What We Can Lift

What types of concrete can you lift in Kansas City?

Foamjection can lift and stabilize many types of concrete, including:

- Driveways

- Sidewalks and walkways

- Patios and porches

- Garage floors

- Steps and stoops

- Pool decks

- Interior concrete floors

and other concrete slabs around homes and properties in Kansas City.

You can explore residential & commercial services here:

Residential Concrete Leveling / Commercial Concrete Leveling

Can you lift stamped or decorative concrete without damaging it?

Yes, in many cases. Polyurethane foam lifting is a controlled process that gently raises the slab from below. Because the slab itself is not removed or broken apart, decorative and stamped concrete can often be lifted while preserving its appearance. Check our concrete lifting work

Can you lift concrete inside a home or building?

Yes. Foamjection is commonly used for interior concrete floors in homes, warehouses, factories, and other buildings. The equipment is compact, and the process does not require large machinery or demolition, making it ideal for indoor applications.

What happens if there’s a big empty space under my slab?

Large voids are one of the main reasons concrete settles. Foamjection’s expanding foam is designed to flow into empty spaces beneath the slab, filling those voids and restoring support. This not only lifts the concrete but also stabilizes the soil to help prevent future settlement. Know more

Large voids are one of the main reasons concrete settles. Foamjection’s expanding foam is designed to flow into empty spaces beneath the slab, filling those voids and restoring support. This not only lifts the concrete but also stabilizes the soil to help prevent future settlement. Know more

Cost, Estimates, and Warranty

How much does concrete lifting cost in Kansas City?

The cost depends on several factors, including the size of the slab, how far it has settled, and the condition of the soil underneath. In most cases, concrete lifting costs significantly less than full replacement. The best way to get accurate pricing is through a free quote.

The cost depends on several factors, including the size of the slab, how far it has settled, and the condition of the soil underneath. In most cases, concrete lifting costs significantly less than full replacement. The best way to get accurate pricing is through a free quote.

How do I get a free estimate in Kansas City?

You can request a free, no-obligation estimate by visiting our Contact Us page and submitting the form.

What is the quote process like?

After you request a quote, we will schedule a time to stop out and review your concrete issue, assess whether lifting is the right solution, and provide clear pricing and next steps.

How long does your warranty last, and what’s included?

Warranty coverage varies by project, but Foamjection focuses on long-term stabilization—not just lifting the slab. We will explain warranty details clearly before work begins so you know exactly what’s covered.

Concrete Replacement vs. Concrete Raising

Is concrete lifting better than replacing it?

For many homeowners and businesses, yes. Concrete lifting can save up to 70% compared to replacement, avoids demolition, reduces downtime, and keeps existing concrete out of landfills. Replacement is sometimes necessary for severely damaged slabs, but lifting is often the smarter first option.

Process & Timing

How long does the concrete lifting process take?

Most concrete lifting projects are completed in just a few hours. The exact time depends on the size of the slab and the complexity of the job, but it’s much faster than removing and replacing concrete.

Most concrete lifting projects are completed in just a few hours. The exact time depends on the size of the slab and the complexity of the job, but it’s much faster than removing and replacing concrete.

When can I use the surface again?

In most cases, surfaces are ready to use almost immediately after lifting. Polyurethane foam cures quickly, so there’s typically no long waiting period before walking or driving on the concrete.

In most cases, surfaces are ready to use almost immediately after lifting. Polyurethane foam cures quickly, so there’s typically no long waiting period before walking or driving on the concrete.

What will my concrete look like after it’s lifted?

After lifting, the slab will be level and stable. The small injection holes are patched and blended to be as discreet as possible. While patches may remain visible up close, the surface is far less noticeable than cracked or sunken concrete.

Is concrete lifting messy or disruptive?

No. The process is clean and minimally invasive. There’s no heavy demolition, no large equipment tearing up your yard, and no extended curing time like with replacement.

Will there be heavy trucks on my lawn?

Typically, no. Foamjection uses compact equipment and hoses that allow technicians to reach the slab without driving heavy vehicles across your lawn or landscaping.

Is there any maintenance needed after lifting?

Basic maintenance helps extend results, such as sealing joints, managing drainage, and making sure downspouts direct water away from concrete. Your technician can provide guidance based on your specific situation.

Trust, Safety & Differentiators

Is your foam safe for the environment?

Yes. The polyurethane foam used by Foamjection is engineered for safety, and durability and moisture resistance. It does not leach harmful chemicals into the soil or groundwater. And it adds very little weight to the soil, helps reduce waste by extending the life of existing concrete, and is manufactured with up to 40% renewable content.

What is HMI, and why does it matter?

HMI is an industry leader in concrete lifting equipment, training, and systems, with over 50 years of experience and more than 100,000 successful lifts nationwide. Foamjection is powered by HMI technology, which means every project follows a tested, professional process—not guesswork. Learn more about HMI.

HMI is an industry leader in concrete lifting equipment, training, and systems, with over 50 years of experience and more than 100,000 successful lifts nationwide. Foamjection is powered by HMI technology, which means every project follows a tested, professional process—not guesswork. Learn more about HMI.

Why does my concrete keep sinking, even after it’s been lifted or replaced?

Concrete can continue to sink if the underlying soil problems aren’t addressed. Foamjection focuses on stabilization by filling voids and strengthening weak soil—not just lifting the slab—helping reduce the chances of recurring settlement.

Concrete can continue to sink if the underlying soil problems aren’t addressed. Foamjection focuses on stabilization by filling voids and strengthening weak soil—not just lifting the slab—helping reduce the chances of recurring settlement.

Foamjection Near You

Serving 30+ States and Expanding

Foamjection helps homeowners with expert foam concrete leveling throughout.

America's #1 Concrete Lifting Company

Get a Free Concrete Leveling Estimate

Whether your driveway is sinking, your sidewalk is a trip hazard, or your patio is dropping near the foundation, Foamjection delivers a fast, clean, cost-effective fix using proven foam lifting technology.