Factory Floor Leveling

Home » Commercial Concrete Lifting » Factory Floors

Uneven factory floors can interfere with production, create safety risks for employees, and affect how equipment operates. Settled concrete can lead to trip hazards, vibration in machinery, and water pooling in low areas. Over time, these issues can slow workflows, increase wear on equipment, and raise maintenance and liability concerns.

Foamjection quickly lifts sunken factory floor slabs back into position without removing or replacing the concrete. Our polyurethane concrete lifting process restores support beneath the slab, improves floor stability, and helps keep operations running with minimal disruption—often completed quickly and without shutting down production.

Why Factory Floors Sink

Factory floors sink when the soil beneath the slab loses stability. Common causes include:

- Soil erosion beneath large slab areas

- Heavy machinery and constant load stress

- Poor drainage under the floor

- Long-term soil movement

- Voids forming beneath the concrete

As support weakens, slabs settle unevenly and create safety and performance issues.

Signs Your Factory Floor Needs Leveling

You may need factory floor leveling if you notice:

- Uneven or sunken floor sections

- Equipment vibration or misalignment

- Gaps or uneven joints between slabs

- Water pooling on the floor

- Increased wear on machinery or carts

Addressing these issues early helps maintain productivity and reduce downtime.

If settlement affects connected areas, interior floor leveling, loading docks & ramps, or parking lot leveling may also be needed to stabilize surrounding concrete and maintain consistent floor height throughout the facility.

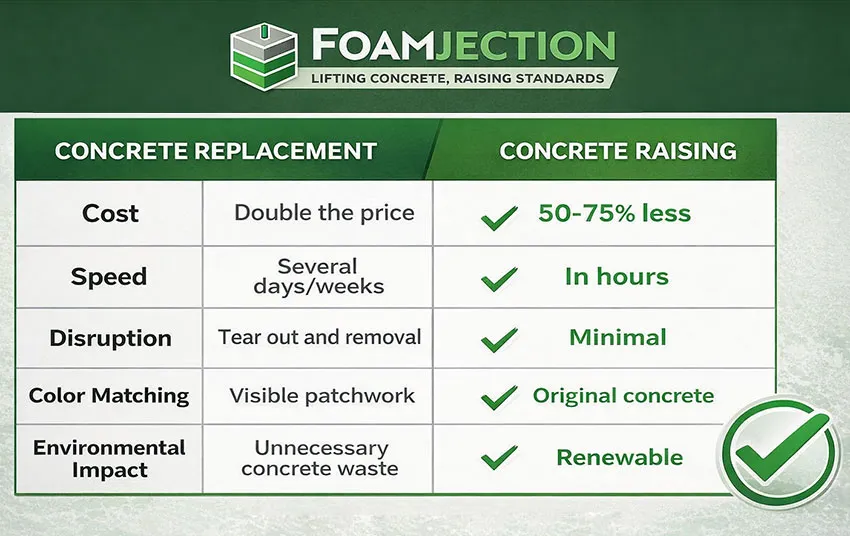

With Foamjection, you get:

A solution that costs 50–70% less

A Process completed in hours, not days

A precise, durable slab lifting solution

Eco-friendly materials

Local certified expertise

Our Fix: Polyurethane Factory Floor Leveling

Foamjection levels factory floors by injecting high-density polyurethane foam beneath the slab. The foam expands to fill voids, lift the concrete, and restore firm support below the surface.

- Small access holes are drilled

- Foam is injected beneath the factory floor

- The slab is lifted and stabilized

- Holes are patched after lifting

Most factory floor leveling projects are completed efficiently, and many surfaces are ready for use the same day.

Why Property Owners Choose Factory Floor Leveling

Property owners choose factory floor leveling because it corrects uneven slabs without extended shutdowns or demolition. Lifting restores safe working surfaces and helps protect equipment and production flow.

- Costs less than replacement

- No tear-out or heavy equipment

- Minimal disruption to operations

- Fast completion time

- Long-term support under the slab

For factory floors that are intact but uneven, leveling is often the most practical solution.

The Benefits of Foam Factory Floor Leveling

- Reduced downtime

- Improved safety for workers and equipment

- Lightweight foam that does not overload soil

- Water-resistant material

- Controlled, precise lifting

Factory Floor Leveling Questions

What causes factory floors to settle?

Factory floors settle due to soil erosion, heavy equipment loads, poor drainage, and long-term soil movement beneath large slabs.

Is factory floor leveling better than replacement?

In many cases, yes. Leveling costs far less, takes far less time, and avoids major disruption to operations.

Is polyurethane foam strong enough for constant industrial traffic?

Yes. High-density polyurethane foam is designed to support industrial loads and frequent traffic. It restores firm support beneath the slab without adding excess weight to the soil.

How long does factory floor leveling take?

Most factory floor leveling repairs only take a few hours – in one visit. We do our best to schedule around your operations, so you stay up and running.

Will production need to stop during leveling?

In most cases no. Most jobs are completed in a few hours, and we do our best to keep your operations running like normal.

Can leveling be done around fixed equipment and production lines?

In many cases, yes. Repairs can often be performed around fixed equipment and production areas. The approach depends on slab conditions and load requirements, which are reviewed during the evaluation.

Does it create odors or fumes inside the facility?

No. The eco-friendly polyurethane foam is injected beneath the concrete and cures quickly. It does not produce lingering odors or fumes, making it safe for indoor factory environments.

Are the repair holes noticeable after leveling?

The holes are small and patched after lifting.

Can leveling help reduce vibration affecting machinery or conveyors?

Yes. Uneven or unsupported slabs can contribute to vibration issues. By restoring support beneath the floor, Foamjection can help create a more stable surface and reduce vibration caused by settlement.

Will leveling help reduce trip hazards around workstations and walkways?

Yes. Leveling removes uneven transitions and low spots, helping improve safety around workstations, walkways, and high-traffic areas.

Can leveling improve floor drainage?

Yes. Leveling restores proper slope so water drains correctly across the floor.

How do I get a FREE estimate?

Easy. Request a FREE estimate by visiting our Contact Us page.

Our team will review your request and explain the next steps.

Edit Template

Foamjection Near You

Serving 30+ States and Expanding

Foamjection helps homeowners with expert foam concrete leveling throughout.