SEAWALL REPAIR & stabilization

Home » Seawall Repair

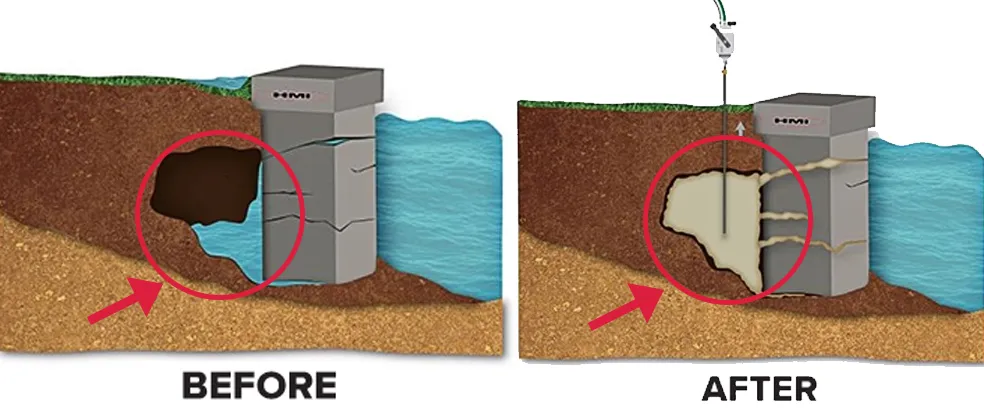

Restore Support Behind Your Seawall Without Excavation or Replacement

Seawalls protect shorelines, properties, and structures from erosion and water damage. Over time, however, water movement can wash soil out from behind the wall, creating hidden voids that weaken support. This often leads to sinking walkways, leaning walls, cracking concrete, or sudden surface collapse near the edge.

Foamjection provides a targeted solution for seawall repair by stabilizing the soil behind and beneath the wall. Using high–density waterproof polyurethane foam, we fill voids, stop ongoing erosion, and restore support—without tearing out the seawall or disturbing the shoreline.

Why Sea Walls Fail

Sea wall problems usually start below the surface. Common causes include:

- Soil erosion from water movement

- Tidal action washing material away

- Poor drainage behind the wall

- Voids forming under or behind the structure

- Long-term soil settlement

When soil is lost, the wall no longer has the support it needs to remain stable.

When Sea Wall Repair Is the Right Choice

Sea wall repair is often a good solution when:

- The wall is intact but shifting

- Voids are present behind the wall

- Soil loss is visible or suspected

- Replacement is not yet required

Early repair helps slow further erosion and extends the life of the structure.

With Foamjection, you get:

A solution that costs 50–70% less

A Process completed in hours, not days

A precise, durable slab lifting solution

Eco-friendly materials

Local certified expertise

Our Fix: Polyurethane Foam Sea Wall Repair

Foamjection repairs sea walls by injecting high-density polyurethane foam into voids behind and beneath the wall.

As the foam expands, it:

- Fills empty space

- Displaces trapped water

- Restores firm support

- Helps stabilize the wall

This method avoids heavy excavation and limits disturbance to the surrounding area.

The Foamjection Seawall Crack Repair Process

Here is a step-by-step breakdown of how we’ll fix your seawall:

Inspection &

Evaluation

A Foamjection contractor will thoroughly inspect your seawall to understand the damage. We’ll determine the best repair plan to stabilize your seawall for the long term.

Polyurethane Foam Injection

We’ll use advanced technology to inject high-density polyurethane foam into any voids or cracks behind your seawall. The foam will expand to fill these gaps, compact the loose soil and provide the structural support needed to prevent further damage.

Seawall Stabilization & Waterproofing

Once the foam hardens, it will reinforce the foundation of your seawall. This new, solid base will prevent water intrusion and soil erosion. This process strengthens seawalls without needing expensive and disruptive digging or rebuilding.

Final Assessment &

Long-Term Protection

Our contractors will perform a final check to ensure stability after the complete polyurethane injection.

Why Polyurethane Foam Works for Sea Walls

Polyurethane foam is well-suited for shoreline environments because it is:

- Lightweight and strong

- Water-resistant

- Fast-curing

- Long-lasting below the surface

Unlike traditional fill materials, the foam does not wash out once it cures.

Seawall Repair FAQ

Common signs your seawall needs repairs include cracks, leaning, soil loss behind the wall, rust stains, voids or sinkholes, or water seeping through. If you notice any of these, it’s best to schedule an inspection.

Most seawall issues are caused by soil erosion behind the wall. Water movement, tidal action, wave pressure, poor drainage, and aging backfill can slowly wash soil away, leaving empty pockets that compromise stability.

Foam-based repair involves injecting expanding polyurethane foam behind or beneath the seawall. The foam fills voids, displaces water, and strengthens weak soil, restoring support without excavation or structural replacement.

Most seawall repairs using polyurethane foam injection can be completed in one day with minimal disruption.

Yes! In many cases, seawall repair is a viable alternative to full replacement. Advanced repair methods like polyurethane foam injection can extend the life of your seawall for years at a fraction of the cost of replacement.

No. Foam injection limits the need for excavation and reduces disruption to the surrounding area.

In many cases, yes. The foam is waterproof and expands to fill empty spaces, helping block water pathways that allow soil to wash out. This helps slow or stop ongoing erosion behind the wall.

No. Polyurethane foam is water-resistant and remains stable after curing.

Yes. Once cured, the foam becomes an inert, stable material beneath the surface. It is waterproof, does not leach, and is designed for long-term use in wet environments.

In many cases, yes — partially. Foam-based seawall repair can stabilize and help correct minor to moderate lean by filling voids and restoring support behind and beneath the wall. When the loss of soil is the main cause of movement, injecting polyurethane foam can stop further shifting and, in some situations, gently improve alignment.

That said, foam repair is not intended to completely re-set severely leaning or structurally failed seawalls. If a wall has major structural damage, significant rotation, or failed anchoring, additional structural repairs may be required.

Foamjection evaluates each seawall individually. When conditions allow, foam stabilization is often the least invasive way to improve stability, reduce further movement, and extend the life of the existing seawall—without excavation or replacement.

The foam is designed for long-term performance and does not break down under normal conditions.

Common warning signs include sinking soil or concrete near the wall, voids or soft spots behind the seawall, cracking slabs, leaning walls, or sudden changes in ground level along the shoreline.

Yes. Foamjection has access to a geotechnical engineer as part of our team to help evaluate soil conditions, settlement causes, and long-term stability—especially for complex projects like seawalls, commercial slabs, and infrastructure repairs. This ensures each solution is engineered for the conditions below the surface, not just the concrete you see.

Contact Foamjection to schedule an evaluation. We’ll assess the seawall, identify erosion or voids, and provide a clear, no-obligation recommendation.

Foamjection Near You

Serving 30+ States and Expanding

Foamjection helps homeowners with expert foam concrete leveling throughout.